In the age of advanced technology, few innovations have captivated our imagination and revolutionized various industries as profoundly as 3D printing. Although its applications are vast, one sector where 3D printing has caused a significant impact is healthcare. The ability to craft personalized, patient-specific medical solutions has established 3D printing as a transformative force, driving innovation in the field of medicine to unparalleled levels.

Table of Contents

What is 3-D printing

3D printing, often referred to as additive manufacturing, is a transformative method that allows the production of three-dimensional items from a computer-aided design or blueprint. This technique constructs the final product by depositing material in successive layers, contrasting with subtractive manufacturing techniques where material is removed from a larger piece.

Here are 5 steps of how 3D printing typically works:

- Creation Process: It all commences with the development of a 3D digital model of the intended object. This model can be crafted using computer-aided design (CAD) software or generated through 3D scanning of an existing object.

- Layer Division: Specialized software plays a pivotal role by taking the digital design and segmenting it into a sequence of slim, horizontal cross-sectional layers.

- Fabrication: The 3D printer takes its cues from the software, meticulously depositing material layer upon layer to assemble the object. The material options are diverse and may encompass plastics, metals, ceramics, and more. In certain cases, advanced 3D printers even employ multiple materials simultaneously.

- Material Solidification: Depending on the 3D printing technology employed, the material is typically solidified, fused, or cured subsequent to its deposition. This can entail various processes such as heating, cooling, ultraviolet light exposure, laser treatment, or chemical reactions.

- Final Product: Once all layers have been added and the material has solidified, the final 3D-printed object is ready for use. Depending on the specific application, it may necessitate post-processing procedures such as cleaning, sanding, or painting to attain the desired aesthetics and functionality.

3D printing finds applications across a range of industries such as aerospace, healthcare, automotive, manufacturing, and consumer products. It is employed for purposes like prototyping, the production of customized parts, rapid manufacturing, and more.

But We are discussing about Healthcare:

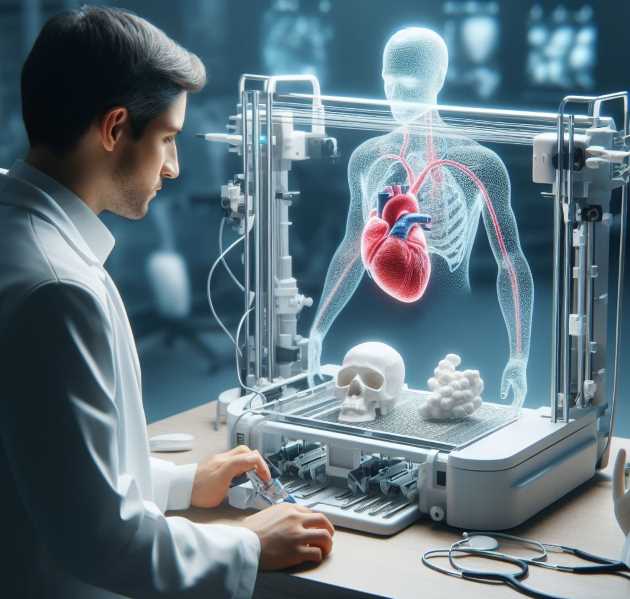

The Healing Power of 3D Printing

Envision a scenario where medical professionals can create customized solutions for patients with the precision of a skilled artisan. This represents the potential of 3D printing in healthcare, and it is steadily transforming the landscape of medicine. Here are a few ways this innovative technology is reshaping the field.

1. Bespoke Prosthetics and Orthopedics

3D printing in healthcare has been heralded for its role in producing individualized prosthetics and orthopedic implants. While conventional prosthetics serve their purpose, they sometimes lack the desired comfort and adaptability. With 3D printing, prosthetic devices are designed to align seamlessly with an individual’s specific anatomy, ensuring greater comfort and enhanced life quality.

In the realm of orthopedics, 3D techniques are changing the dynamics of joint replacement surgeries. Surgeons can now fashion implants that are an exact match for patients, minimizing complications and hastening recovery times. This is especially promising for joint-related interventions.

2. Tailored Implants

3D printing offers the capability to produce specialized implants, ranging from dental fixtures to cranial fittings. These are not just generic pieces; they’re designed in sync with the distinct anatomical attributes of a patient, promoting a better fit and fewer complications. This even translates to cost-effective dental solutions that are readily available.

3. Advanced Drug Delivery

The wonders of 3D printing aren’t just physical. Pioneering research is underway to determine how this method can facilitate sophisticated drug delivery mechanisms. By personalizing the drug release patterns according to patient needs, 3D-printed pharmaceuticals have the potential to transform treatments, amplifying their effectiveness while diminishing adverse effects. This promises safer and more dependable medication capsules.

4. Bioprinting Potential

Bioprinting, or the art of creating viable human organs via 3D printing, represents one of its most ambitious applications. While still nascent, the technology holds the promise of combatting the acute shortage of organs available for transplants. There’s research focused on producing organs from a patient’s cells, which would mitigate rejection risks and remove dependence on organ donors. This is a monumental stride, especially considering the high costs associated with organ transplants, promising affordable organ solutions for those in need.

Challenges and Looking Ahead

The promises of 3D printing in healthcare are immense, but it’s not devoid of challenges. Aspects like regulations, quality assurances, and ethical dilemmas are pivotal concerns as this tech evolves.

Peering into the future, 3D printing’s footprint in healthcare is destined to grow. With relentless innovation, we can expect myriad groundbreaking applications, charting the path toward a healthcare system that’s more attuned to individual needs. Yet, challenges like managing the volume of items produced by 3D printers persist, underscoring the need for more advanced tech solutions.

In light of these impressive advancements, it’s evident that 3D printing isn’t merely altering our medical strategies—it’s sculpting a brighter health-focused future. This innovation brings us closer to an era where healthcare is more customized, streamlined, and widely accessible.

for more new knowledge click here–> Read New